Plastics

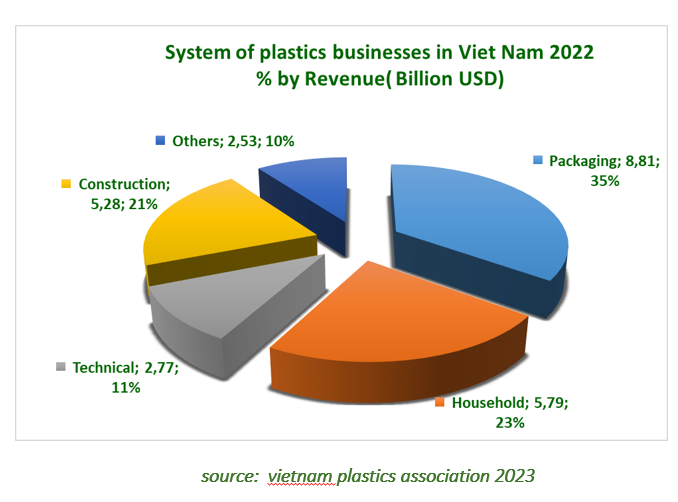

According to statistics from the Vietnam Plastics Association, in terms of the structure of Vietnam's plastic industry by revenue in 2022, construction plastics ranked 3rd with 5.28 billion USD, after packaging plastics at 8.81 billion USD and household plastics at 5.79 billion USD.

According to statistics from the Vietnam Plastics Association, in terms of the structure of Vietnam's plastic industry by revenue in 2022, construction plastics ranked 3rd with 5.28 billion USD, after packaging plastics at 8.81 billion USD and household plastics at 5.79 billion USD. in terms of output, construction plastics ranked 4th after packaging plastics, household plastics, and engineering plastics.

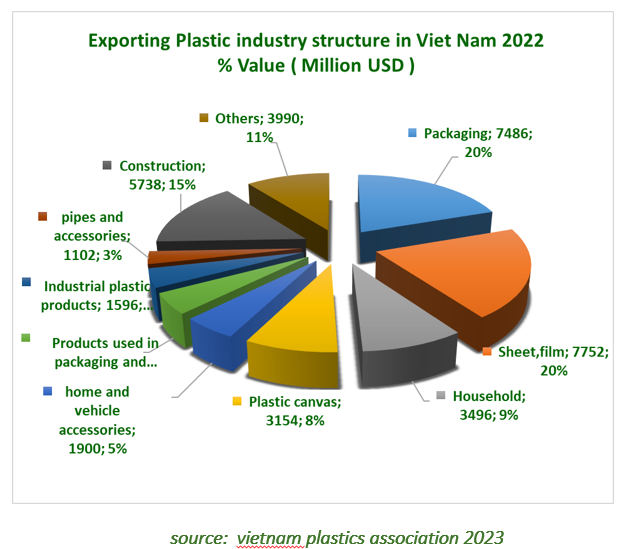

In 2022, the three plastic products of Vietnam with the largest export turnover are plastic products such as sheets, films, packaging and construction, with the total export turnover of these three plastic products accounting for 55.6% of the total export turnover of plastic products in 2022.

Besides the profits, the export of Vietnamese plastic products also faces many challenges in the world markets. The Russia-Ukraine conflict and the consequences of the global supply chain, high energy and food prices, are reducing hopes of recovery after the Covid 19 pandemic.

The world economy is greatly affected by inflationary pressure that is forecast to last and the energy crisis that is at risk of becoming more serious in Europe, leading to many consequences

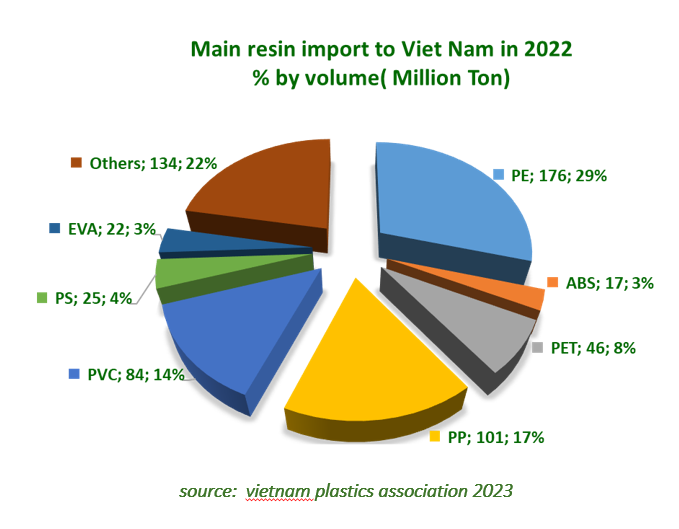

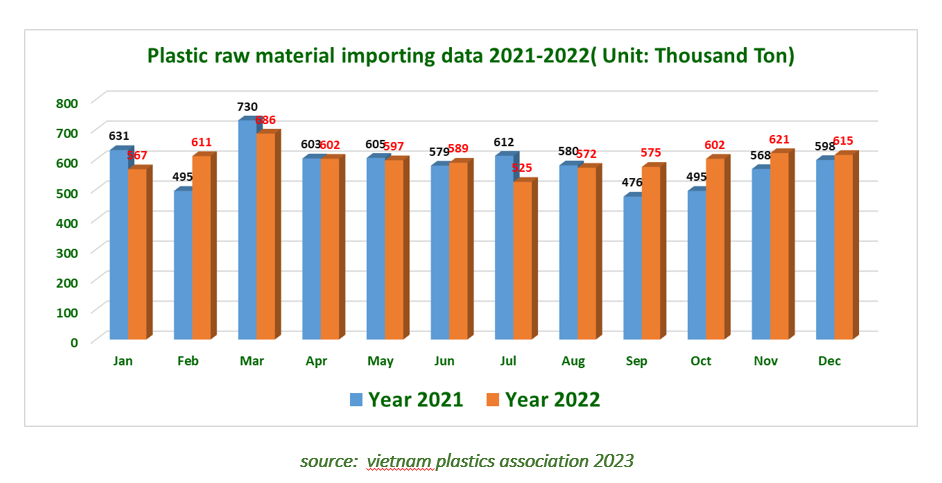

Imports of raw plastic materials in 2022 will reach 3,684 million tons with a value of 6,758 billion USD, up 0.4% in volume and 11.1% in value compared to 2021.

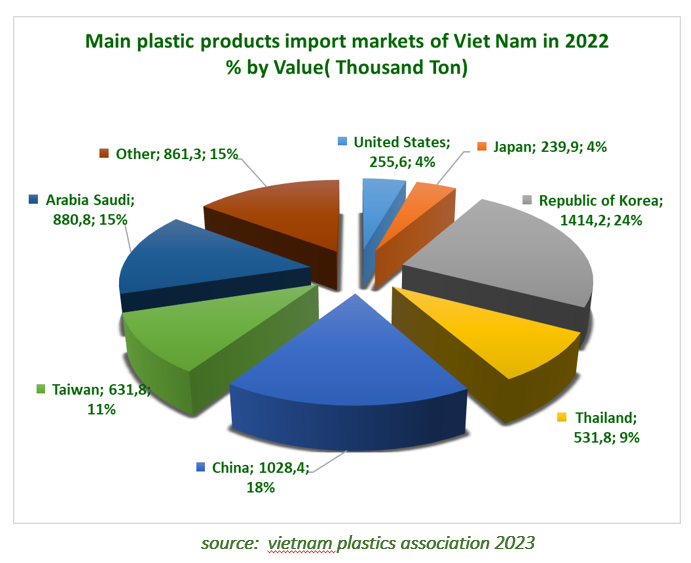

According to statistics, plastic imports in 2022 from the Korean, Indonesian, and Russian markets increased sharply; from the Taiwanese, Malaysian, Singaporean, and American markets decreased compared to 2021.

In which, Korea reached 1.414 million tons with a value of 2.38 billion USD, an increase of 25.5% in volume and 24.3% in value compared to 2021, accounting for 24% of the total amount of imported plastic materials in Vietnam.

China reached 1.028 million tons with a value of 2.085 billion USD, an increase of 0.5% in volume and 10.1% in value compared to 2021, accounting for 18% of the total amount of imported plastic materials in Vietnam.

In 2022, in general, Vietnamese plastic products will increase in export to major markets. only export turnover to the Chinese market will continue to decrease. of which, plastic product exports to the United States market will reach the highest level of 1.85 billion USD, accounting for 40% of total plastic product export turnover. Compared to 2021, plastic product export turnover to the United States increased by 23.9%. Japan is the second largest export market, reaching 634.4 million USD, accounting for 13.7% of total plastic product export turnover. compared to 2021, plastic product export turnover to the Japanese market increased by 13.4%.

In general, total imported plastic materials in the first 6 months of 2022 decreased compared to the first 6 months of 2021, but in the last 6 months of 2022, it increased slightly again.

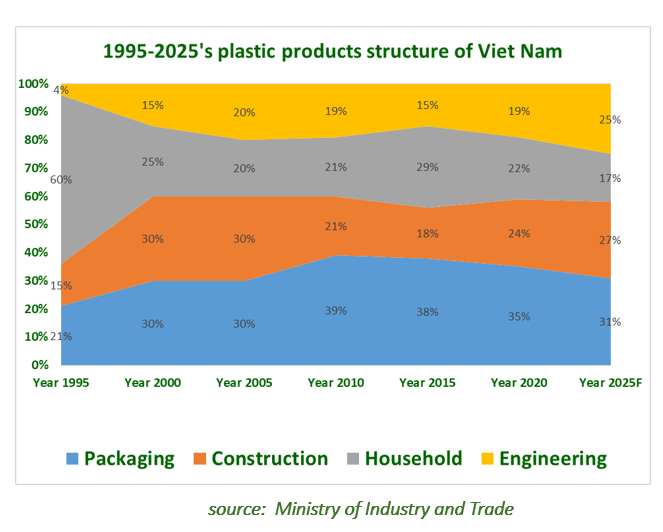

In the period 2005 - 2015 in the value structure of the Vietnamese plastic industry, the two segments of household plastics and packaging plastics accounted for 56-60%. In the period 2015-2017, the structure of the Vietnamese plastic industry is shifting from segments with low added value such as packaging plastics and household plastics to production segments with higher added value such as construction plastics and engineering plastics.

In the value structure of the industry in 2017, the construction plastics segment has a value of about 3.6 billion USD, up 60% yoy, accounting for 24% and the engineering plastics segment has a value of about 2.8 billion USD, up 50% yoy, accounting for 19% according to the industry development plan (Decision/2992-BCT), the two segments of construction plastics and household plastics are expected to contribute 27% and 25% respectively to the value structure of the plastics industry in 2025.

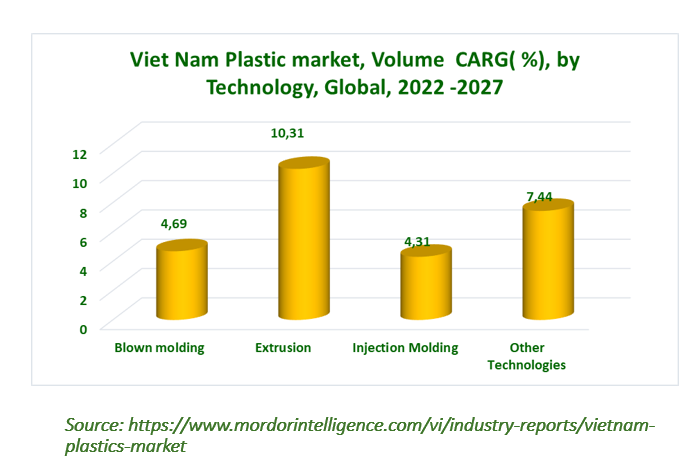

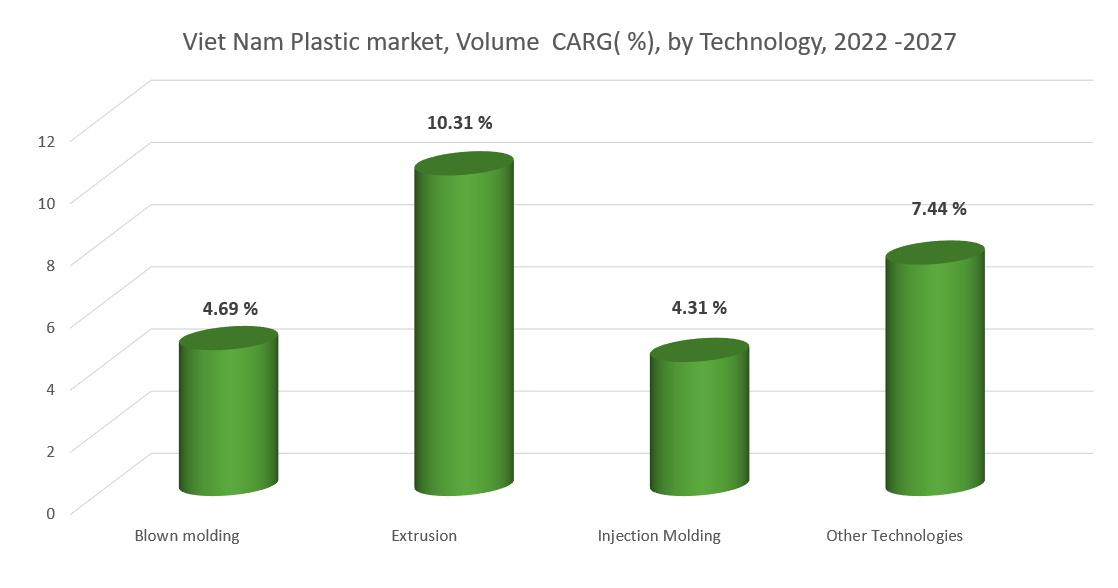

In Vietnam, extrusion technology is used to produce products such as PVC, PE, aluminum and plastic pipes, fibers, PVC doors, frames, roofing sheets, and wall panels. The extrusion process requires lower production costs and faster setup times.

However, it provides medium precision and is mostly suitable for parts with uniform and uncomplicated cross-sections.

This technology is mainly used in construction activities, the main products include PVC, HDPE, PPR pipes, profiles, plastic doors and windows, panels, and furniture.

Based on the above aspects, extrusion technology is expected to dominate the market.

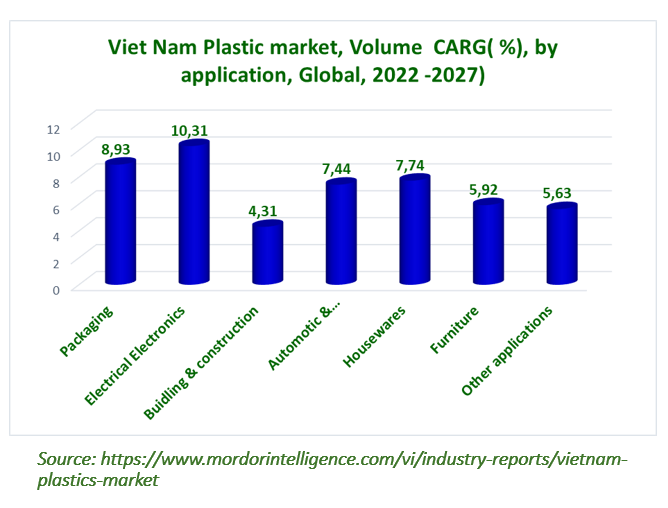

Packaging accounts for the largest market share in the Vietnamese plastics market. Factors such as lightweight, resistance to heat, chemicals, and corrosion make plastic a viable option for packaging purposes in the Vietnamese market.

In the packaging industry, plastics are used for healthcare packaging, food and beverage packaging, consumer packaged goods, consumer and personal care packaging, as well as home and garden packaging.

With a growth rate of 15% to 20% in the coming years, the packaging industry is one of the fastest-growing industries in Vietnam. More than 900 factories are currently operating in this sector, with about 70% of them located in the Southern region, mainly in Ho Chi Minh City, Binh Duong, and Dong Nai.

Thus, based on the above aspects, the packaging segment is predicted to dominate the market

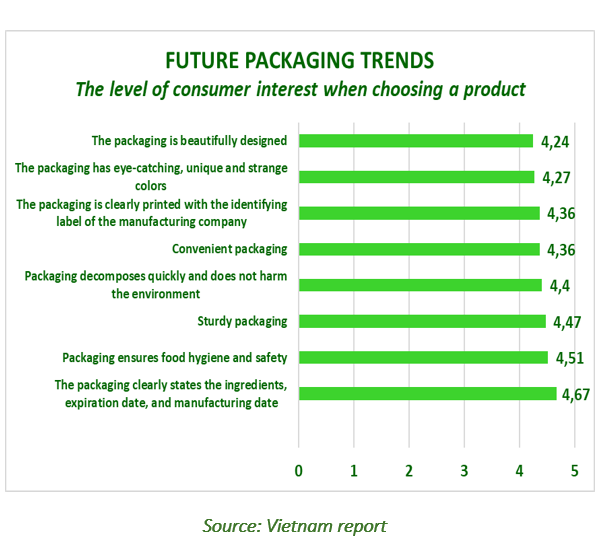

According to experts, the function of packaging is divided into two types: technical function and marketing function. with the technical function, as its name suggests, packaging is evaluated according to the following criteria: (1) packaging clearly prints ingredients, expiry date, and date of manufacture; (2) packaging ensures safety; (3) packaging is sturdy; (4) packaging decomposes quickly, does not harm the environment; and (5) packaging is convenient. according to a survey conducted by Vietnam Report in September 2022, consumers are very interested in the technical function of packaging when shopping and pay special attention to information about ingredients, expiry date, and date of manufacture printed on the product packaging (4.67/5). 100% of consumers when buying goods are first interested in the ingredients, expiry date, and expiry date printed on the packaging to make sure that the goods have a good list of ingredients and the product is still within the expiry date. protecting the product inside is one of the important functions, helping to separate the product from external factors that damage the product. therefore, sturdy packaging is also one of the factors that customers care about when using packaging. currently, environmental protection is one of the factors that consumers care about the most. some businesses have been "boycotted" by consumers for using packaging that is not environmentally friendly. therefore, the criteria for evaluating packaging that decomposes quickly and does not harm the environment is one of the criteria that consumers pay attention to (4.40/5).

Many businesses often only see packaging as a technical function, choosing the cheapest, fastest solution, and do not fully believe that investing in packaging can make the customer experience of the product better. according to a consumer survey by Vietnam report, packaging with clearly printed labels (4.36) is the factor that consumers care about the most in terms of marketing function. in terms of eye-catching colors and beautiful designs, young consumers are more influenced by these two factors. businesses are increasingly aware that they need to impress customers not only with a good product but also with better packaging. therefore, this supporting industry has a lot of growth potential.

VIETNAM POLYVINYL CHLORIDE MARKET

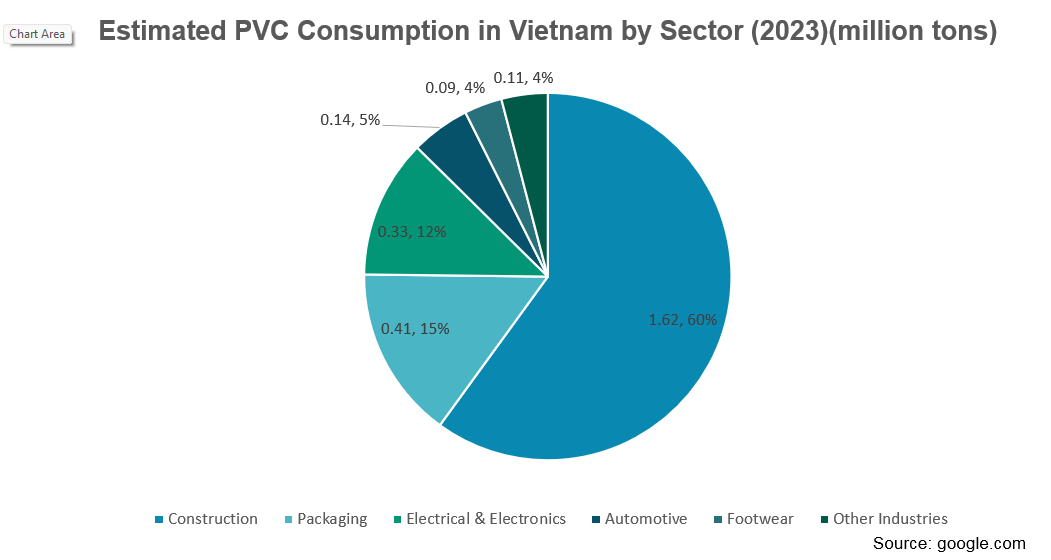

The Vietnam PVC market is experiencing steady growth driven by rapid urbanization, infrastructure development, and manufacturing growth. The construction industry is a significant consumer of PVC, particularly for pipes, fittings, and profiles. Additionally, the rising demand for PVC in other sectors like automotive manufacturing, electrical cables, and packaging further propels market expansion.

POLYVINYL CHLORIDE CAPACITY IN VIETNAM

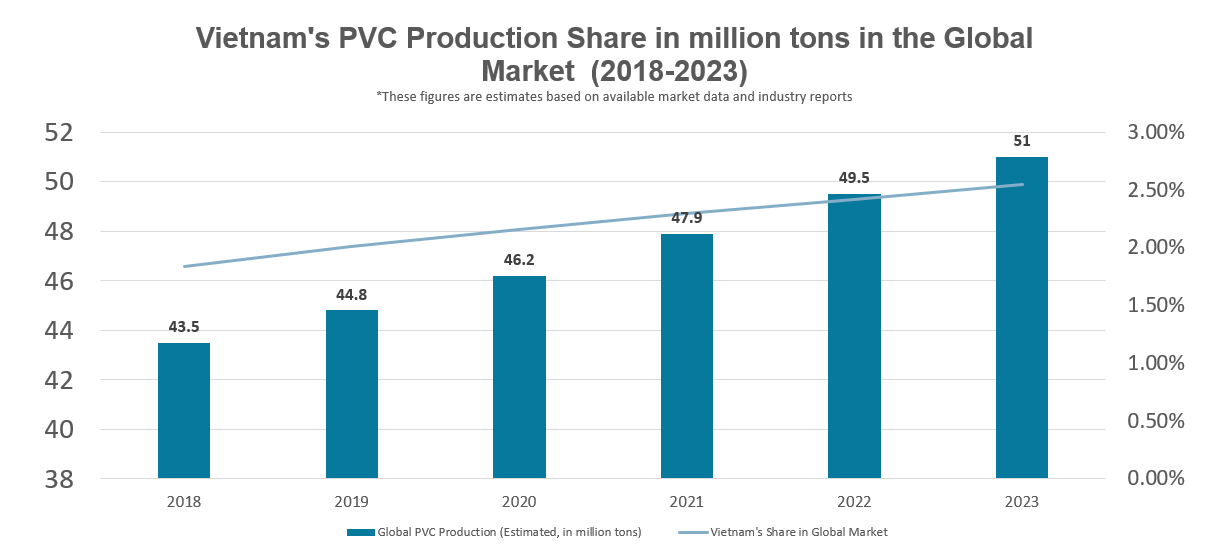

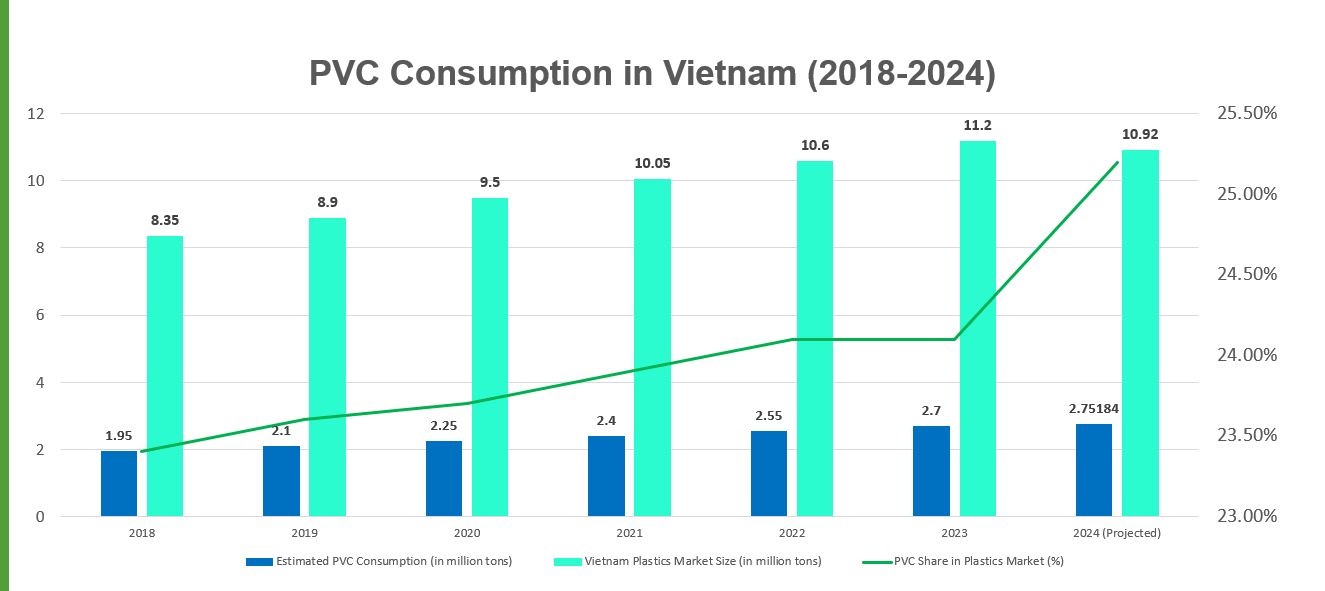

While precise data on Vietnam's 2023 PVC production capacity and its share in the global and regional markets remains elusive, the nation's burgeoning plastics industry is poised for significant growth. With a projected market size of 10.92 million tons in 2024, Vietnam is solidifying its position as a key player in the plastics arena. PVC, a major component of this market, is not only fueling industrial expansion but also playing a pivotal role in the country's economic development.

Key Factors Driving PVC Demand in Vietnam:

- Construction Boom: Rapid urbanization and infrastructure projects have fueled massive demand for PVC in pipes, fittings, profiles, and other essential building materials. This sector remains the primary driver of PVC consumption in Vietnam.

- Industrial Expansion: The growth of manufacturing industries, particularly automotive, electronics, and packaging, has significantly increased the need for PVC in various components, including wires, cables, packaging films, and interior parts.

- Rising Consumer Spending: With increasing disposable incomes, Vietnamese consumers are demanding more goods made with PVC, such as footwear, toys, and household items, further boosting PVC consumption.

These three key factors combined have created a perfect storm of demand for PVC, making it a vital material for Vietnam's continued economic development. However, this growing consumption also necessitates a focus on sustainable practices to mitigate the environmental impact of PVC production and disposal.

Consumers of Polyvinyl Chloride in Vietnam:

A. Construction Industry (Largest Consumer):

Pipes & Fittings: PVC is the material of choice for water supply, drainage, and sewage systems due to its durability, corrosion resistance, and cost-effectiveness.

Profiles: PVC profiles are widely used for windows, doors, and other building components due to their thermal insulation, soundproofing, and aesthetic appeal.

Roofing & Cladding: PVC sheets are used for roofing, wall cladding, and other exterior applications, offering protection from the elements and reducing construction costs.

Flooring & Wall Coverings: PVC flooring and wall coverings are popular choices for residential and commercial buildings due to their durability, easy maintenance, and versatility in design.

B. Automotive Industry:

Interior Components: PVC is used for dashboards, door panels, seat covers, and other interior components due to its lightweight, flexibility, and cost-effectiveness.

Wires & Cables: PVC insulation provides protection and durability to electrical wires and cables used in vehicles.

Underbody Coatings: PVC coatings protect car underbodies from corrosion and damage.

C. Packaging Industry:

Films & Sheets: PVC films and sheets are widely used for packaging various products, including food, pharmaceuticals, and consumer goods.

Bottles & Containers: PVC bottles and containers are used for packaging beverages, household chemicals, and other products.

Blister Packaging: PVC blister packs are commonly used for packaging consumer goods and pharmaceuticals.

D. Electrical Industry:

Cables & Wires: PVC is the primary insulation material for electrical cables and wires, providing excellent electrical insulation and fire resistance.

Cable Ducts & Trunking: PVC is used for cable ducts and trunking, protecting electrical wiring and ensuring safe installation.

Electrical Fittings & Accessories: PVC is used for various electrical fittings and accessories like switch boxes, junction boxes, and conduits.

E. Other Industries:

Medical Devices: PVC is used in medical tubing, bags, and other disposable medical devices due to its biocompatibility and cost-effectiveness.

Footwear: PVC is used for shoe soles, straps, and other components due to its durability, flexibility, and water resistance.

Consumer Goods: PVC is used in various consumer goods like toys, stationery, and household items.

Market Trends and Key Consumers of PVC in Vietnam:

|

Sector |

Consumption Trend |

Key Drivers |

Future Outlook |

|

Construction |

Rapid Growth |

- Urbanization and infrastructure development |

Positive |

|

Packaging |

Steady Growth |

- Rising consumer spending and e-commerce |

Stable |

|

Electrical & Electronics |

Moderate Growth |

- Industrial expansion and manufacturing growth |

Positive |

|

Automotive |

Steady Growth |

- Growing middle class and rising car ownership |

Positive |

|

Footwear |

Slow Growth |

- Competition from other materials |

Uncertain |

|

Other Industries |

Moderate Growth |

- Expansion of various sectors like agriculture, healthcare, and consumer goods |

Positive |

Future Outlook:

The demand for PVC in Vietnam is expected to remain strong in the coming years, driven by continued urbanization, infrastructure development, and industrial growth. The government's focus on affordable housing and renewable energy is likely to further boost PVC consumption. However, the industry needs to address environmental concerns and adopt sustainable practices to ensure long-term growth and acceptance.

Summary:

Vietnam's PVC market is booming, driven by rapid urbanization, industrial expansion, and rising consumer spending. The construction sector is the leading consumer, while packaging, electrical/electronics, and automotive sectors also contribute significantly.

PVC production in Vietnam is estimated to exceed 1 million tons annually, with major players leading the charge. Consumption is projected to reach 2.86 million tons in 2024, highlighting PVC's vital role in the nation's economy.

While challenges like raw material dependency and environmental concerns exist, the outlook for Vietnam's PVC market remains positive. Continued growth is expected, driven by infrastructure development and government support, with potential for expanding regional exports.